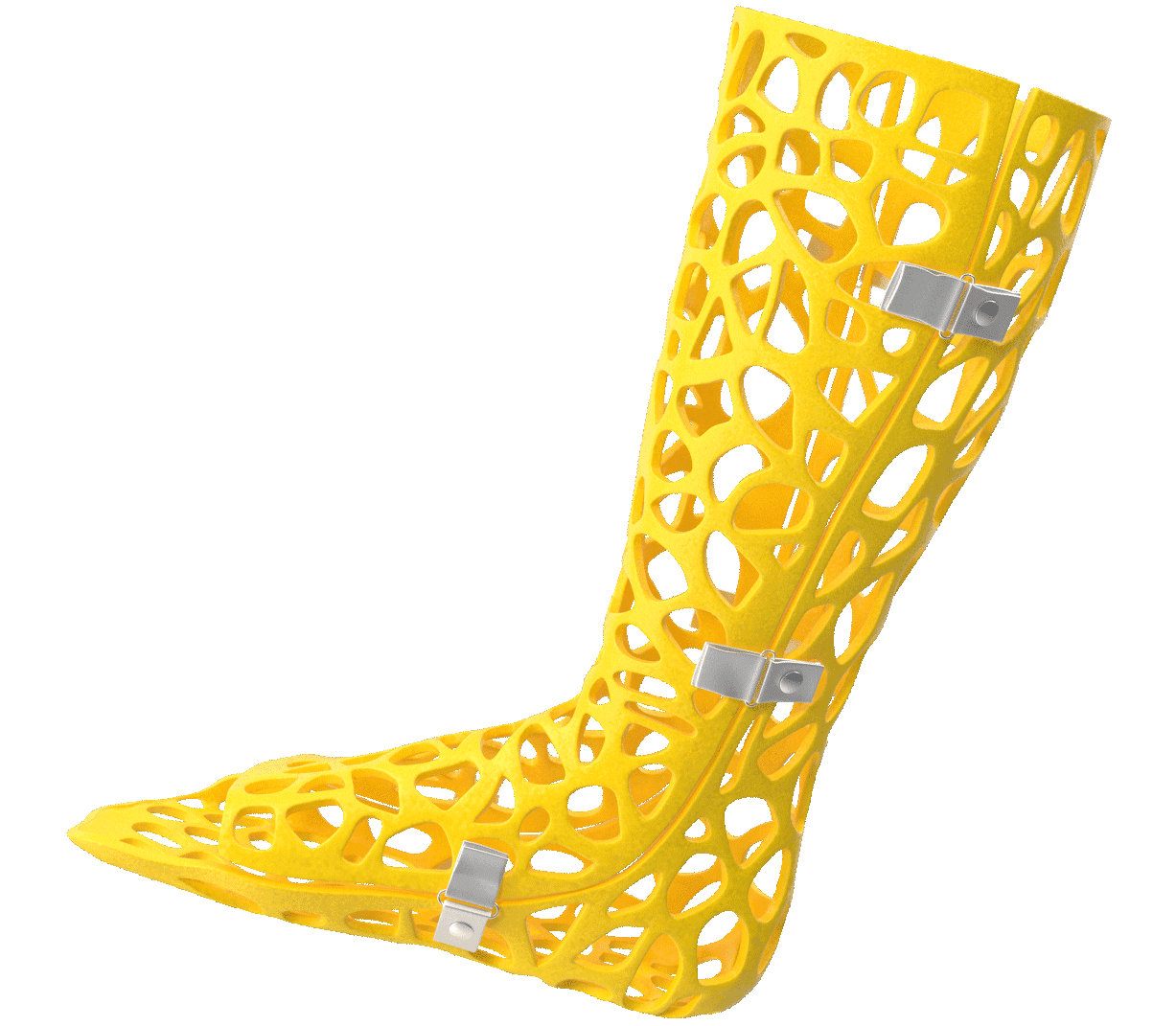

En la UAM diseñan prótesis que mejoran las condiciones de movilidad

Una prótesis impresa en 3D fue el desarrollo realizado desde Laboratorio de Mecánica Computacional y Experimental de la...

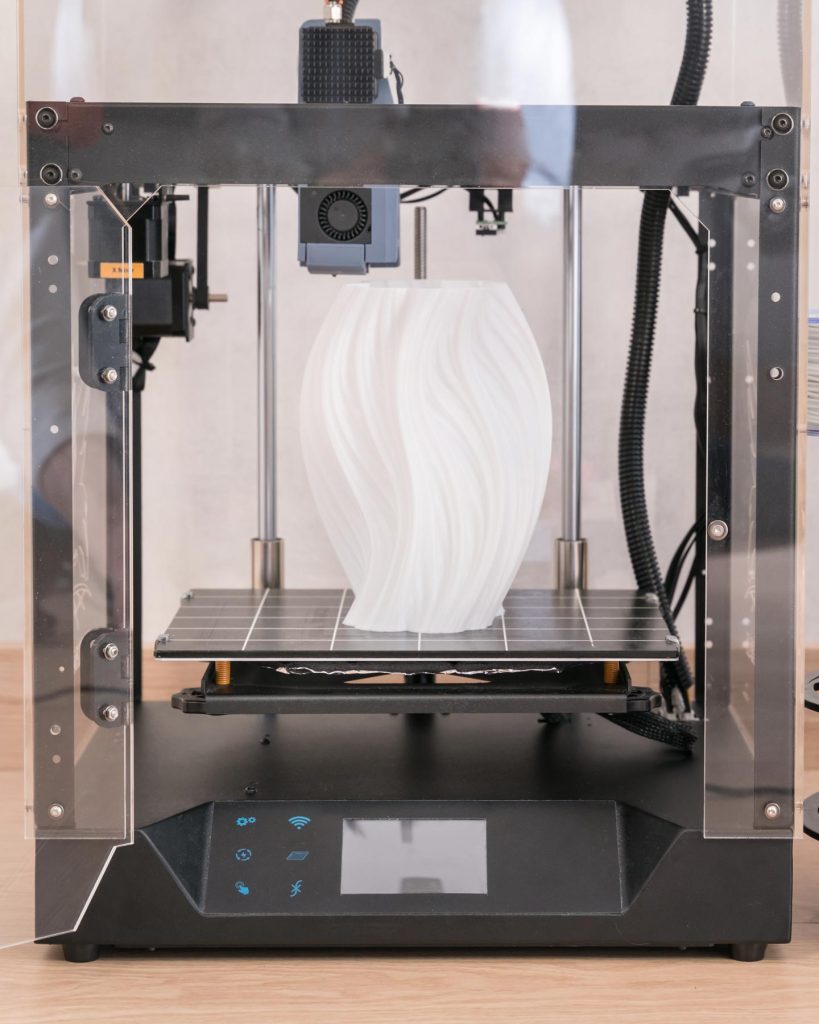

Transformamos ideas en realidades tangibles a través de la innovación en impresión 3D. Nos comprometemos a ofrecer soluciones personalizadas y de alta calidad, fomentando la creatividad, ayudando a la naturaleza y promoviendo la sostenibilidad. Buscamos ser líderes en la industria, impulsando la tecnología para hacer accesible la fabricación aditiva a todos, desde emprendedores hasta grandes empresas, y contribuir al desarrollo de un futuro más eficiente y responsable. Además, buscamos mejorar la calidad de vida de los animales a través de soluciones innovadoras y personalizadas ofreciendo productos ortopédicos accesibles y de alta calidad.

Diseño e impresion 3D de productos ortopédicos para animales, COVERS y decoracion de protesis para personas

Diseñamos y creamos piezas para decoración vehicular. Por medio de la impresión 3D podemos brindarle repuestos vehiculares, que no se encuentran en el mercado.

Diseñamos y creamos piezas que no se encuentran en el mercado. Por medio de la impresión 3D podemos brindarle extender la vida útil de sus maquinarias

Servicios de INGENIERÍA INVERSA, Transformación de estructuras y objetos en modelos digitales precisos y manipulables.

En el año 2019 Alejandro Castaño Ortiz funda ACO3 Impresiones, empresa que se dedicaba a fotocopias, impresiones y papelería, a través del tiempo los servicios fueron mejorando teniendo en cuenta la necesidad de nuestros clientes y fortaleciéndose en el área del diseño, ofreciendo servicios de señalización, animación, diseño 2D y 3D, diseño de publicidad y estampados.

En el año 2024 encontramos nuevas necesidades no solo en nuestros clientes si no también en los animales y es como nace ACO 3Dimpresiones S.A.S empresa que no solo dedicada al diseño 2D y 3D si no también a la impresión 3D de productos ortopédicos para animales, diseño e impresión 3D de repuestos para maquinarias industriales y mecánicas, artículos 3D y repuestos para todo tipo de vehículos, impresión 3D de artículos personalizados y decorativos y servicio de Escaneo 3D.

Hoy en día en ACO 3Dimpresiones S.A.S no solo mejoramos la calidad de vida de nuestros clientes y empresas. También tiene una línea de investigación en el área de productos ortopédicos para animales ( lo que nos permite mejorar la calidad de vida de muchos animales) y productos decorativos que permiten personalizar prótesis y férulas para personas.

ACO 3Dimpresiones transforma ideas en realidades tangibles a través de la innovación en impresión 3D. Nos comprometemos a ofrecer soluciones personalizadas y de alta calidad, fomentando la creatividad, ayudando a la naturaleza y promoviendo la sostenibilidad. Buscamos ser líderes en la industria, impulsando la tecnología para hacer accesible la fabricación aditiva a todos, desde emprendedores hasta grandes empresas, y contribuir al desarrollo de un futuro más eficiente y responsable. Además, buscamos mejorar la calidad de vida de los animales a través de soluciones innovadoras y personalizadas ofreciendo productos ortopédicos accesibles y de alta calidad.

"En ACO 3Dimpresiones S.A.S, nos proponemos ser líderes en innovación y sostenibilidad, transformando ideas en realidades tangibles. Nuestra visión es ofrecer soluciones personalizadas que fomenten la creatividad y la eficiencia. Nos comprometemos a utilizar materiales ecológicos y procesos responsables, contribuyendo a un futuro más sostenible. Queremos ser el socio preferido en la creación de prototipos, productos y piezas únicas, impulsando la revolución de la fabricación digital y mejorando la vida de los animales, nuestros clientes y comunidades."

La satisfacción de nuestros clientes es nuestra mayor satisfacción.

Años de Experiencia en el mercado

Procesos de Investigación Desarrollados

Nivel de satisfacción de nuestros clientes

Soluciones prostéticas desarrolladas

Diseño personalizado.

Diseño e impresión de protesis y cubiertas.

Diseño e impresión ornamental de alto valor artístico

Diseño e impresión de elementos para recordación empresarial.

Construimos elementos que no se encuentran en el mercado.

Diseño e impresión de productos de comercialización masiva.

Ingenieria inversa y prototipado ágil de productos.

Diseño e impresión de elementos para la señalización industrial

Ingeniero Industrial egresado de la Corporación Universitaria del Huila (CORHUILA), con especialización en Diseño Asistido por Computador de la Universidad Autónoma de Manizales. Fundador y representante legal de ACO 3Dimpresiones S.A.S. Cuenta con sólida experiencia en diseño, renderizados, simulaciones, animación e impresión 3D de piezas mecánicas, férulas y prótesis para animales. Su capacidad de liderazgo, pasión por la innovación y dominio en manufactura aditiva lo han convertido en un referente en el desarrollo de soluciones personalizadas para diversas industrias y el sector veterinario.

Founder, CEO (Representante Legal)

Ingeniero Industrial con más de 27 años de experiencia laboral. Se ha desempeñado como profesional de apoyo en contratación y proyectos en Sociedad Técnica Sota Ltda., coordinando procesos licitatorios, manejo de plataformas SECOP I y II, planificación estratégica, gestión de personal, proyección de costos y liquidación de proyectos. Actualmente, como gerente de ACO 3Dimpresiones S.A.S, aporta su expertise administrativo y financiero para el crecimiento de la empresa y la consolidación de su línea de innovación en impresión 3D.

COO. (Gerente)

Ingeniero Industrial, con más de 21 años de experiencia laboral, se destaca por su responsabilidad, honestidad y capacidad técnica para el desarrollo de piezas mecánicas, ortopédicas y personalizadas. Actualmente es diseñador industrial y operario en ACO 3Dimpresiones S.A.S., donde lidera procesos de modelado 3D, simulaciones y fabricación de repuestos a medida para maquinaria, automóviles entre otros, contribuyendo a la misión de la empresa de transformar ideas en soluciones tangibles.

Designer (Diseñador)

A través de esta página web o de los canales aquí descritos ponte en contacto con nuestro equipo asesor.

En forma dinámica conoce nuestra propuesta para dar solución a tus necesidades y realiméntala para armonizarla con tus gustos y deseos.

Nuestro equipo diseñará, imprimirá tu producto en el material adecuado y hará entrega del mismo en los plazos acordados.

Paga con nuestra pasarela de pagos y envíanos al correo electrónico la descripción del producto que quieres realizar para tu proceso de merchandizing, el tamaño del elemento no debe superar las dimensiones 5cm x 5cm x 5cm y en 2 días hábiles tendrás tu impresión de prueba y la oferta para su producción en masa

En esta sección ACO3D IMPRESIONES comparte los contenidos y noticias importantes relacionados con la industria de la impresión 3D.

Una prótesis impresa en 3D fue el desarrollo realizado desde Laboratorio de Mecánica Computacional y Experimental de la...